Let's look at how natto is produced and shipped in Japan.

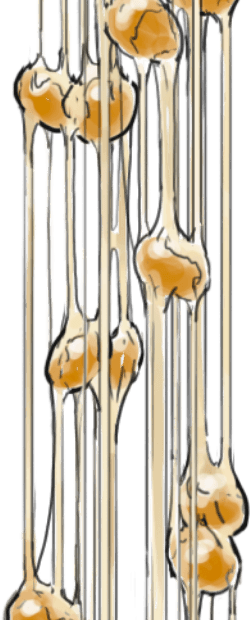

The process of making natto is simple. Boiled soybeans are sprayed with the natto bacillus and then sealed it into packages to ferment and mature. The natto bacillus propagates on the surface of the boiled soybeans, creating the characteristic viscous substances known as "natto threads" and producing its distinctive flavor.

As the natto bacillus propagates, it breaks down the proteins in the soybeans, making them easy for the body to assimilate. It also produces various vitamins and enzymes and other substances that make natto so rich in nutrients.

Unlike other fermented foods such as miso, shoyu and cheese, natto fermentation occurs quickly. The natto is ready approximately 16 to 24 hours after the start of fermentation. So in as little as three days after production starts, the finished natto can be ready for shipment.

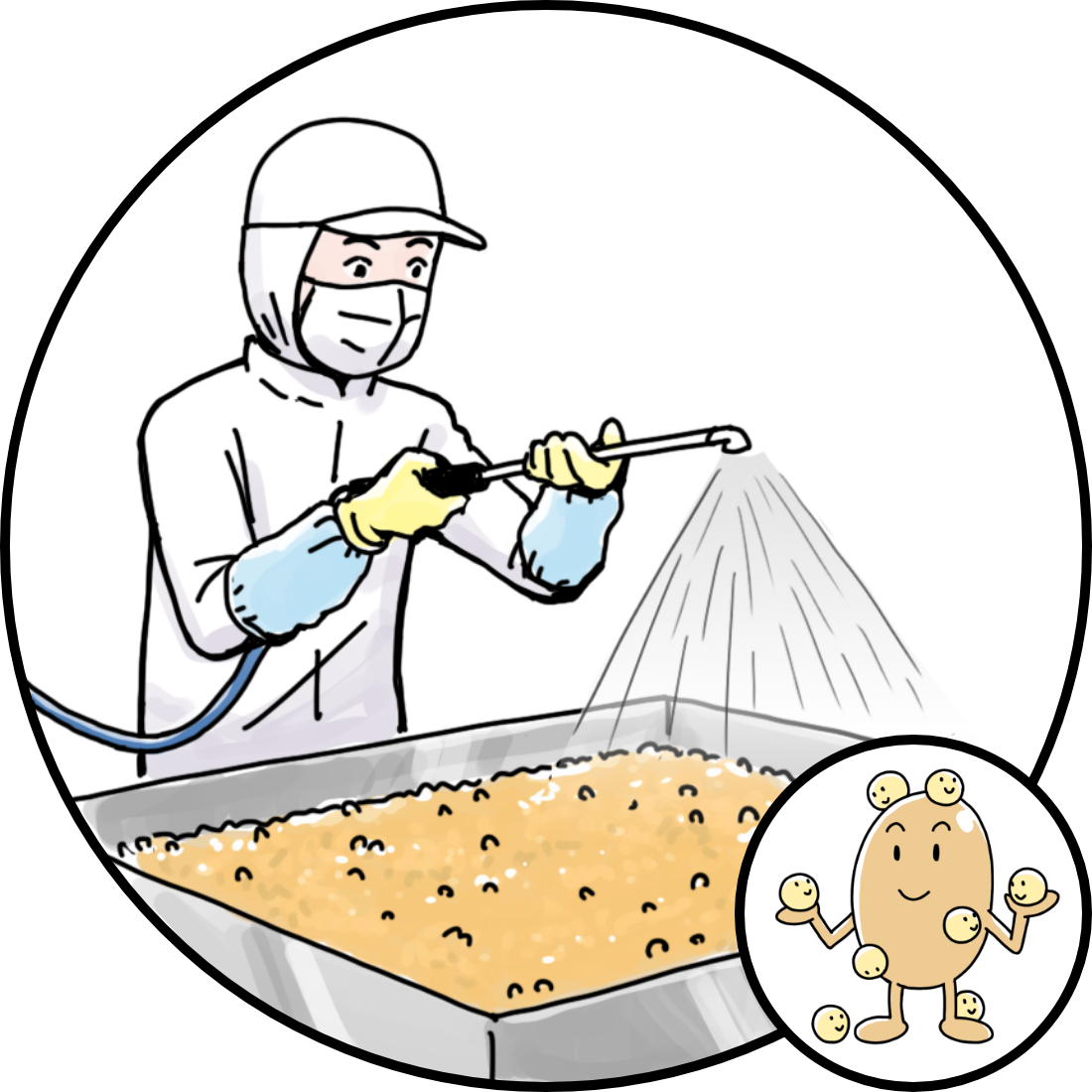

Spraying with the Natto Bacillus

After steaming, the soybeans are sprayed with the natto bacillus.

Read more ...

Container Filling

The soybeans that have been sprayed with the natto bacillus are transferred to a container.

Read more ...

Fermentation

The natto bacillus breaks down the proteins in the soybeans, creating the distinctive viscosity and producing healthy enzymes and vitamins.

Read more ...

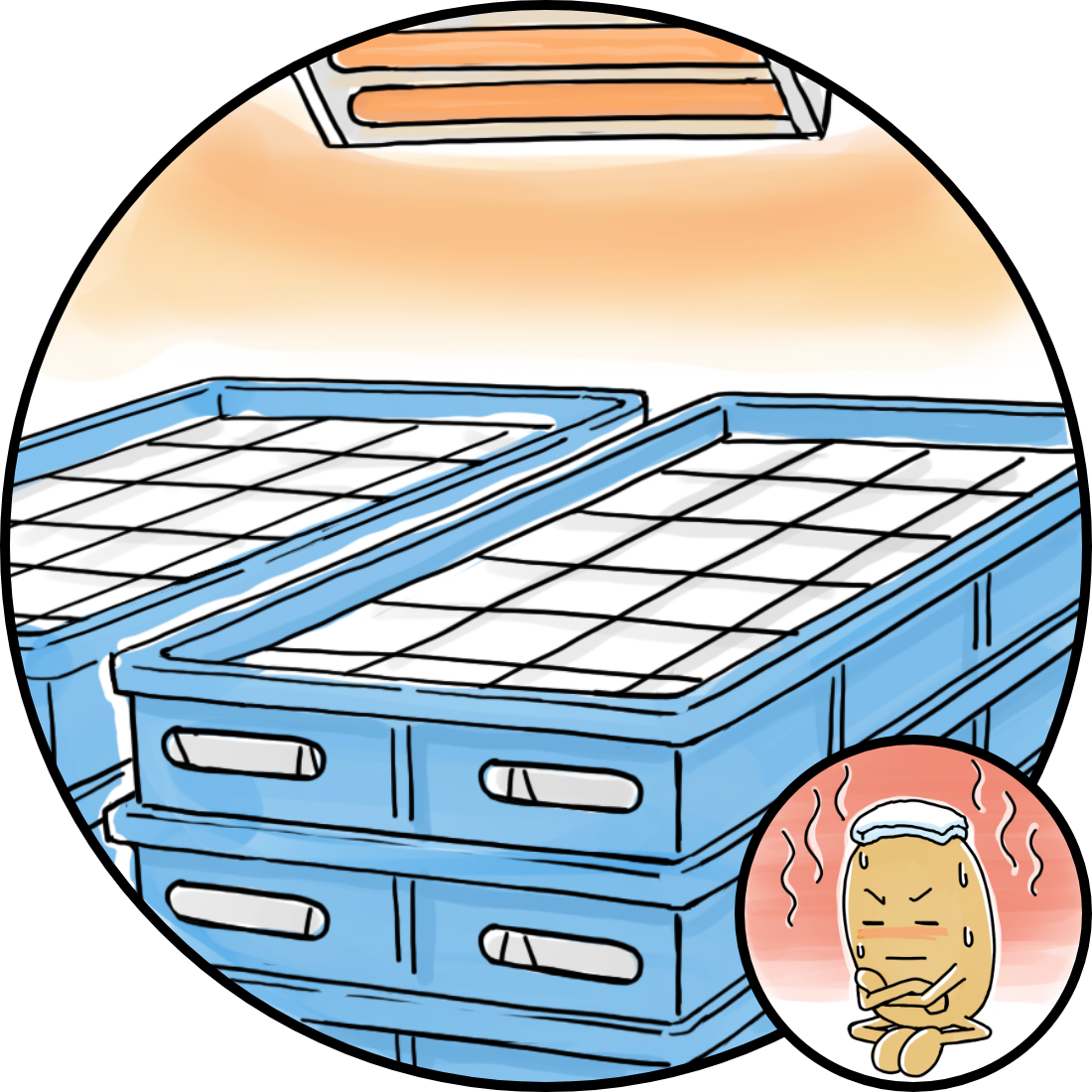

Cooling and Maturation

The natto is cooled and left to mature so it will develop a delicious flavor.

Read more ...

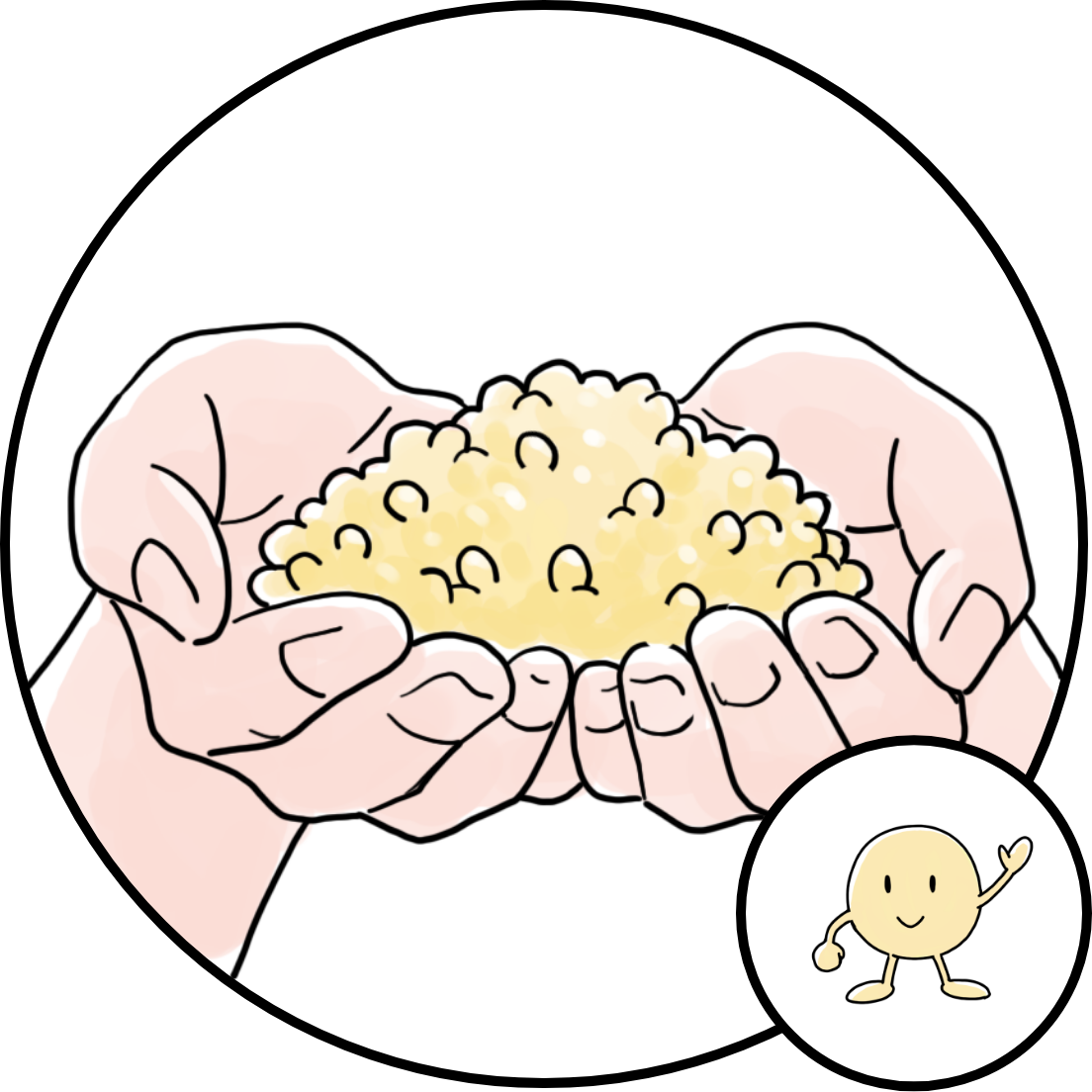

Ingredients

Natto is made from soybeans.

Natto is made from soybeans.

In addition to the soybean varieties that are easy to cultivate, which have been modified and are widely produced, there are also varieties known as "local soybeans" that have been passed down in a few limited areas. The soybeans that ordinary consumers are familiar with, available in supermarkets, convenience stores and so on, are varieties that are widely cultivated in places like Canada and the United States.

The soybeans that are selected are those that are suitable for making natto — in other words, those that will become delicious natto. Whether or not a soybean will turn into delicious natto is said to be determined by factors such as the thickness of the skin and subtle differences in constituent components and so on.

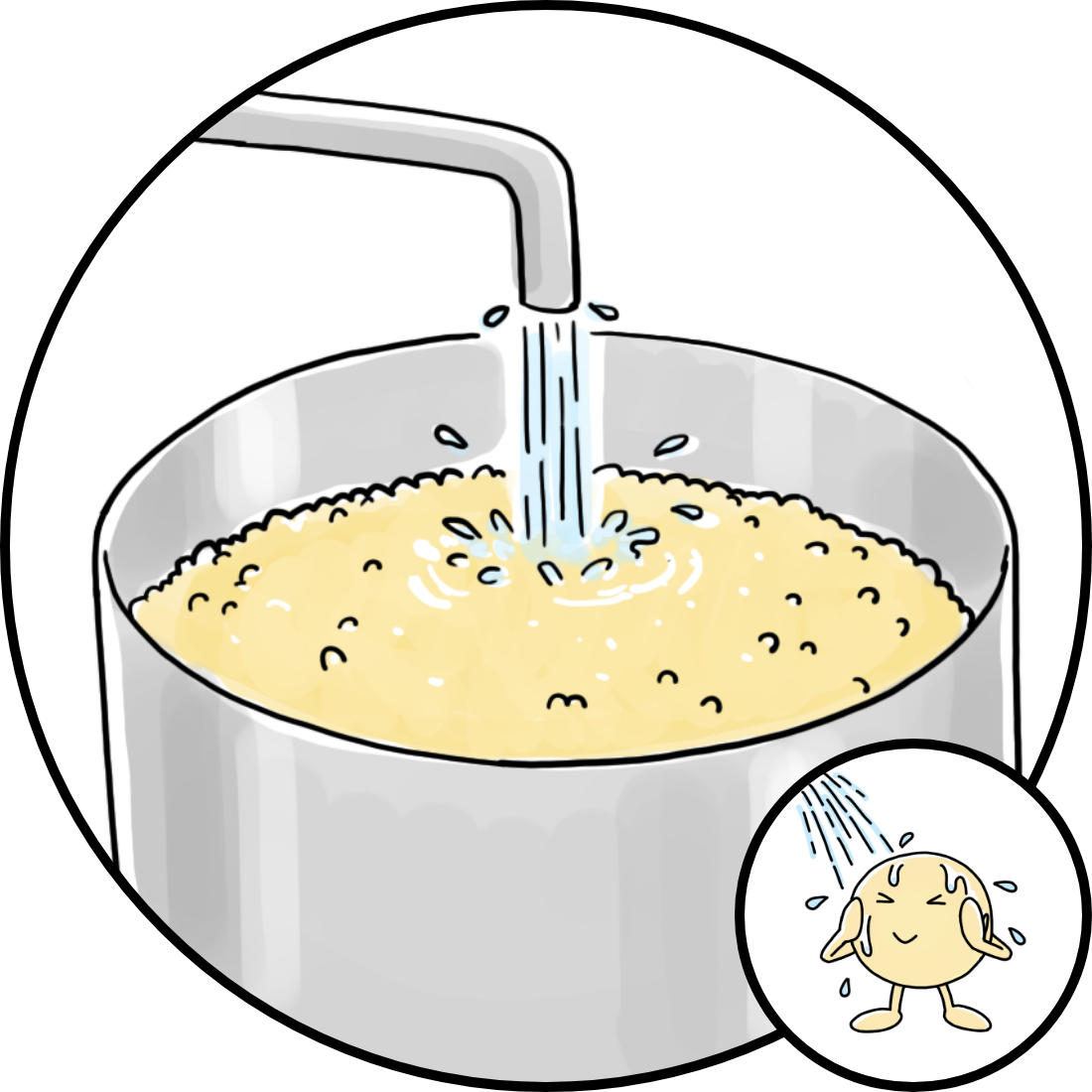

Cleaning

The soybeans are cleaned to remove dirt and impurities.

The soybeans are cleaned to remove dirt and impurities.

Soybeans are shipped after going through a certain degree of selection at the place where they are harvested, and they are stored at a low temperature. In addition, as natto is produced at a natto factory, they are sorted further into more well-organized groups at the factory, and foreign matter is removed. After going through these processes, the soybeans are cleaned.

In the soybean cleaning unit, the soybeans are rinsed with water to remove any remaining foreign matter on their surfaces, and then foreign matter that is not visible to the naked eye is carefully removed. Then the soybeans are physically scrubbed in water and rinsed with clear water until all of the accreted matter originating from the soil has been removed.

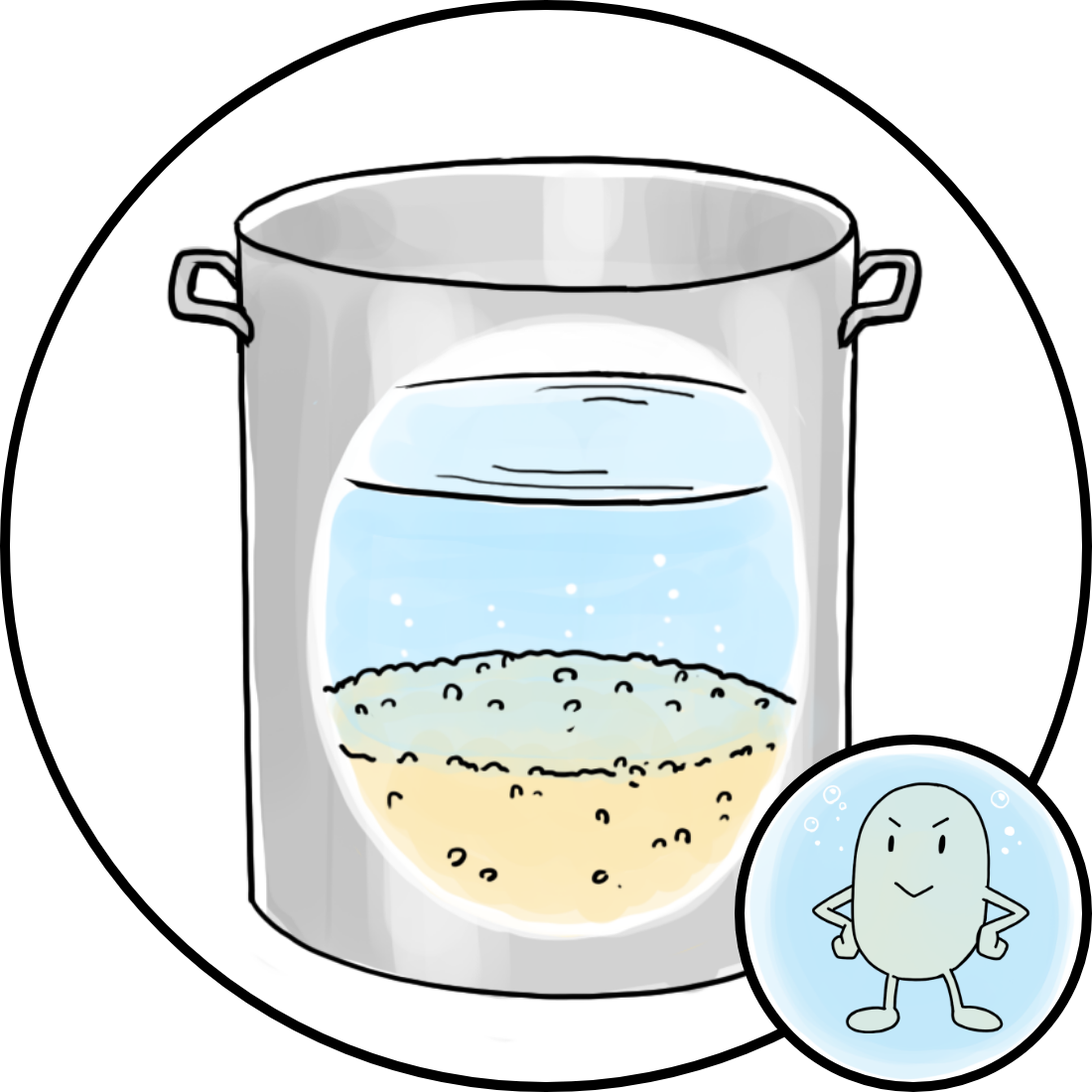

Steeping

The soybeans are placed in water so they will absorb abundant moisture.

The soybeans are placed in water so they will absorb abundant moisture.

Steeping is the process in which the soybeans are immersed in water to allow them to absorb moisture. At large factories, the soybeans are left under sanitary conditions in enormous steeping tanks weighing two to three tons for around 18 hours.

During the steeping process, the soybeans swell until they have approximately doubled in weight. The steeping time must be fine-tuned, as the amount of water that the soybeans will absorb will vary depending on the condition and diameter of the beans, the season, and the temperature of the water.

Workers who have been engaged in natto production for many years can cut a soybean in half and tell at a glance whether it has been steeped for a sufficient period of time. If the interior is even, the beans are suitable; if there are depressions in the interior, the beans have not been steeped for a sufficiently long period of time.

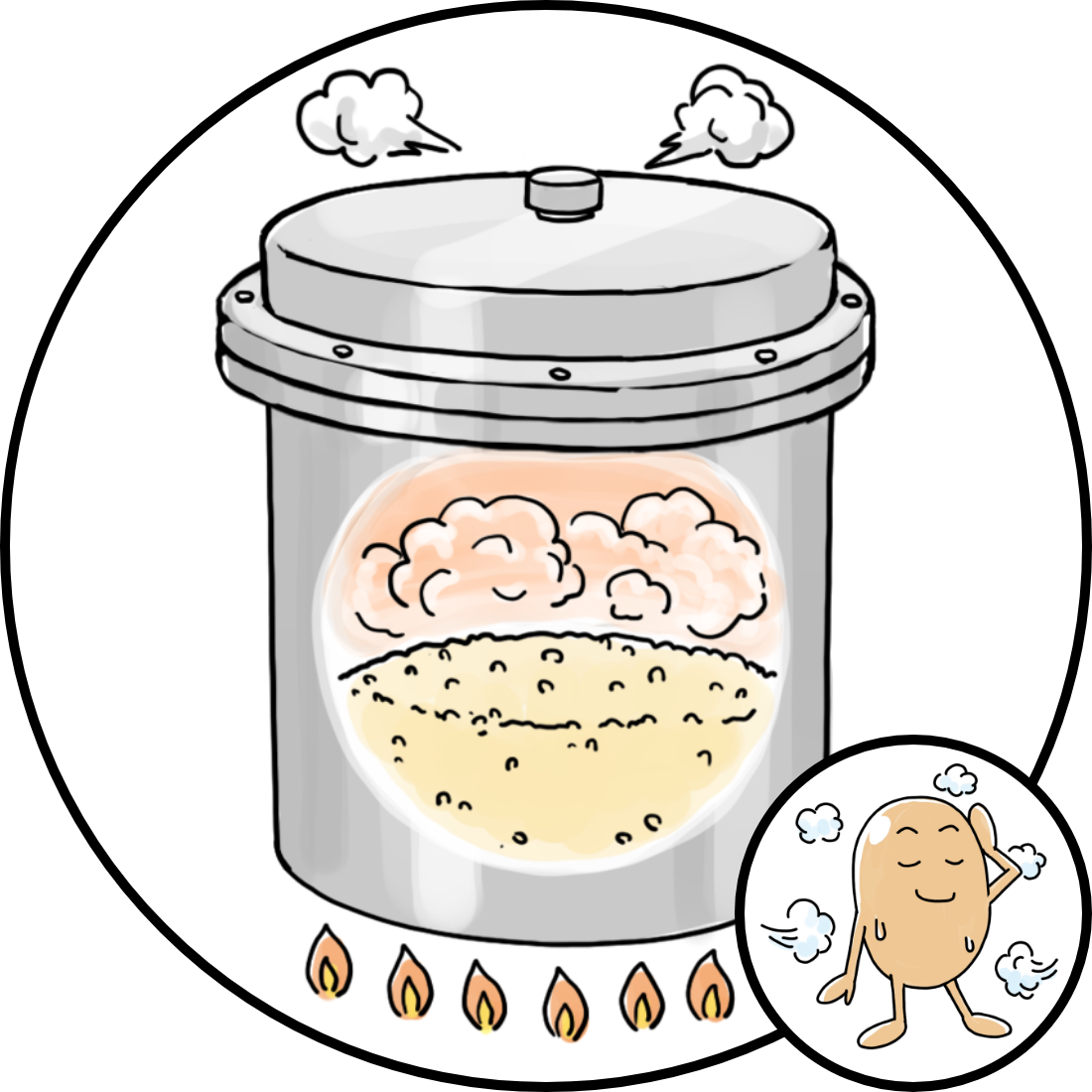

Steaming

The soybeans are steamed in a pressure cooker until they are plump and soft.

The soybeans are steamed in a pressure cooker until they are plump and soft.

Natto is often described as being made from "boiled soybeans," but in actuality they are steamed. The soybeans are placed in a high-pressure steam vessel — in other words, an enormous pressure cooker — that is filled with steam and then pressurized.

This results in a lower loss of nutrients than placing them in a pot to be buffeted about by boiling water.

Soybean steaming is a crucial process, as it affects not only the mouth feel and gloss of the natto but also the fermentation by the natto bacillus in the next process. For this reason, it is carefully controlled.

The steam pressure and duration of steaming are set differently depending on the variety of soybean, but in general the soybeans are steamed for between an hour and an hour and a half after being pressurized.

Spraying with the Natto Bacillus

After steaming, the soybeans are sprayed with the natto bacillus.

After steaming, the soybeans are sprayed with the natto bacillus.

After steaming, the soybeans are sprayed with the natto bacillus. Pure cultivated natto bacillus is rendered into a mist that is sprayed evenly onto the soybeans. As the natto bacillus is a thermoduric bacteria that can withstand high temperatures, the natto bacillus is sprayed when the freshly steamed soybeans are at a temperature of 70 - 90C. Even if the soybeans have been contaminated by other miscellaneous bacteria, these bacteria are killed instantly and are unable to propagate. This shows again the toughness of the natto bacillus.

Container Filling

The soybeans that have been sprayed with the natto bacillus are transferred to a container.

The soybeans that have been sprayed with the natto bacillus are transferred to a container.

The process of packing soybeans into fermentation containers is called "filling." These fermentation packages, which will be shipped as is to consumers, are the familiar styrofoam packages or paper cups that are commonly used to store various types of foods.

As in the case of spraying with the natto bacillus, the filling process is conducted while the soybeans are hot, so as to prevent contamination by other miscellaneous bacteria. However, as oxygen is needed for the natto to ferment properly, a flow of air must be secured. For this reason, the natto is not packed as tightly as possible into the containers. Instead, the natto is placed in the containers gently so ample air pockets will be produced. This ensures that air will get to the natto bacillus and it will be able to conduct active fermentation.

Fermentation

The natto bacillus breaks down the proteins in the soybeans, creating the distinctive viscosity and producing healthy enzymes and vitamins.

The natto bacillus breaks down the proteins in the soybeans, creating the distinctive viscosity and producing healthy enzymes and vitamins.

The natto is placed in a temperature-controlled fermentation chamber called a "muro" and left to ferment for 16 - 24 hours. During this period, the temperature in the chamber is controlled to around 40C, and the humidity is maintained at a high level. When natto bacillus propagation becomes active, the natto produces its own heat, called fermentation heat. At times the fermentation heat may reach 50C. During the fermentation process, a thermometer is placed in a sample container and monitored through mechanical means. The temperature inside the muro is fine-tuned in coordination with monitoring.

During the 16 - 24 hours that they are inside the muro, the soybeans become natto.

Cooling and Maturation

The natto is cooled and left to mature so it will develop a delicious flavor.

The natto containers are removed from the fermentation chamber, and the temperature is lowered to stop fermentation.

At this point, the containers are transferred to a refrigerating chamber and stored for six to eight hours at a temperature of 5C or below, until the natto bacillus is rendered thoroughly dormant.

This process is called maturation. Various components in the natto are stabilized during the process of maturation. It is this process that creates the umami flavor and characteristic viscosity of the natto.

Packaging

The finished natto is packaged.

When the natto in the containers has finished maturing, the containers are labeled and packaged.

Ordinary styrofoam containers are stacked on top of one another in three layers and then enclosed in a label.

At this point, the natto is a finished product that is finally ready to be shipped to customers.